| home | cob | links and suppliers | lath and lime repairs | breathable paints | carpentry | lime repointing | breathable insulation |

|---|

Jack in the Green Builders (run by Glyn Tyler) are based in Mid Devon. Our contact details are at the bottom of the page.

Lime plasters, renders and mortars were commonplace in the UK before the mass production and widespread availability of products such as concrete, cement based renders, modern gypsum plasters and chemical paints.

Most buildings constructed before c. 1919 incorporate lime mortars, renders, plasters and paints. Lime was used in buildings from high status cathedrals and castles through townhouses to the relatively humble cottages, farms and barns which characterise many rural landscapes.

One of the most important aspects of the conservation and maintenance of older buildings is that materials should be replaced like for like. Mass produced materials such as concrete, cement, and modern gypsum plasters have different physical/mechanical properties to traditional and breathable materials and may cause damage to older buildings.

Lime plasters and renders are microporous, they are hard, yet permeable. A good analogy would be a waterproof breathable jacket that stops rain in the form of water, but allows water vapour (or perspiration) to escape, keeping the wearer dry and comfortable!

While lime mortars are breathable, concrete and sand and cement are hard and impermeable. Older buildings, in particular those made of cob , brick and stone, need to breathe so that moisture can pass in and out of walls, maintaining their stability.

Traditionally constructed walls are a holistic breathable system where different building elements work together with the natural environment to keep buildings dry. Poor maintenance or the application of impermeable materials to internal and external walls can upset this delicate balance, allowing moisture to become trapped in walls, causing problems with damp, moulds, and blistering of paint and plaster.

Although there are many reasons why buildings become damp, the primary cause is rainwater penetration. In western Britain, where wind driven rain is especially prevalent, great care must be taken to avoid water ingress. Common causes of damp are leaking gutters and downpipes, cracks in external render or pointing, buildup of external surfaces, splashback onto walls from hard external landscaping, and poor drainage. When moisture ingress occurs through external walls, damp can become trapped behind impermeable internal plasters (including bonding and damp-proofing 'solutions') and plastic based paints.

Lime mortars and plasters are made from solid limestone crushed and burned (traditionally carried out in lime kilns that can still be seen in limestone areas) to form ‘quicklime’. The quicklime is put through a process called ‘slaking’, where it is mixed with water to form lime putty, which then needs to mature for 3 to 6 months. The lime putty is then mixed with sand to produce lime mortars of different consistencies. After application in the form of plaster, render, mortar or limewash, the lime cures and hardens, returning as close as possible to its natural form. This process is often referred to as the ‘natural lime cycle’.

There are various types of building lime available. The limestones from which these are produced contain different amounts of clay minerals (silica and alumina). The amount of these minerals contained within different limestones affects the hardness and breathability of the mortars produced. The softer the substrate (the surface onto which you are applying the lime), the softer the lime needs to be.

Non hydraulic lime (or fat lime) is the most flexible and breathable of the building limes as it is produced from pure limestones containing few or no clay minerals. For this reason, non hydraulic lime (putty or fat lime) is suitable for use on cob, earth and straw bale buildings as these materials are similarly flexible and breathable.

Hydraulic limes are slightly harder and more weather resistant than non hydraulic lime. So where cob demands non hydraulic lime, hydraulic limes are suitable for stonework, damp/wet areas close to ground moisture and external walls subject to wind driven rain. Additives, known as pozzolans, are available to mix into non hydraulic lime which will impart to it hydraulic properties and greater strength.

In exposed areas (such as Cumbria!) prone to large amounts of wind-driven rain and wide temperature variations, we would suggest the use of NHL 3.5 for external work and perhaps NHL 5 for chimneys. Where possible, non-hydraulic (putty) lime should be used for internal plastering whatever the location or substrate.

The principal mechanical difference between lime putty and Natural Hydraulic Limes (NHLs) is that NHLs set underwater (hence the hydraulic in the name). There are three different types of NHLs based on the percentage of silica and aluimina present, and the higher the number, the harder and more impermeable the lime.

Bagged hydrated limes (those commonly sold in general builders merchants) are not suitable for use other than as a plasticiser for cement (most bags of hydrated lime actually say this if you read the back!) as it is produced from various limestone types which don't have to be specified. Hydrated lime (in fact, bagged lime of all types) goes out of date 12 months after production. Hydrated lime is often left sitting around builders merchants, where modern materials are more commmonly purchased. So not only is it's derivation unknown, the lime may have already gone off! There are now many local and web-based retailers that will give advice about the appropriate lime for the job, and with high turnovers, bagged lime bought from them will have been kept dry and be in date! Please see our links page for details.

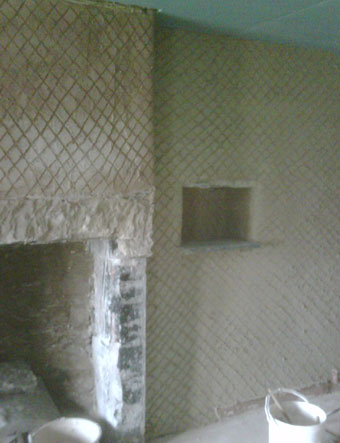

Depending on the character and quality of the substrate, the plastering/rendering process involves three or four main phases where the lime is built up in layers:

•Pugging (or dubbing) out/scat coat: Pugging out generally only takes place on cob and stone walls where gaps or large holes need to be infilled to create a smooth flowing surface onto which full layers of plaster can be applied. Depending on the build, new walls and flattish stone/brick walls can require a ‘scat’ or ‘dashed’ coat of lime slurry which provides a key for the following coats.

•Scratch (or straightening) coat: The scratch coat (it is scratched up to provide a key for the topcoat) is the first complete layer of lime to be applied. It helps to iron out any protrusions or indentations in the wall, and creates a smooth surface onto which to apply the topcoat.

•Top (or floating) coat: The third layer to be applied is the smooth top coat. For external rendering, this is the final coat for a smooth floated finish, or provides a surface for roughdashing. Once this is leather hard, it is rubbed up with a float to iron out any minor bumps and indentations and to create a homogenous surface. For internal work, when this coat has completely dried, it can have a further skim (or finishing) coat applied, or for a more 'rustic' finish, it can be limewashed or painted with breathable paints.

•Finishing (or skim) coat: Internal plastering normally includes a fourth coat of lime finishing plaster. This is a very thin layer which can have a trowelled finish similar to modern gypsum or it can be be floated/sponged up to create a more porous finish. When completely dry, this can be limewashed or painted with breathable paints.

•Dashing/harling. For externally rendered walls, a final coat of lime dashing or harling can be added. This generally contains a larger aggregate. Dashed surfaces increase the surface area of the rendered wall which helps to shed rainwater. For more about dashed/harled coats, see our pointing page

Lime plastering is often described or specified as 'three coat work'. The three coats referred to here are the scratch/straightening coat, the floating/top coat and the skim/finishing coat. Lime plastering surfaces such as brickwork or very flat stonework can be achieved in three coats but very often, preparatory pugging/dubbing out layers are also required!

Have a look at some limework in progress by visiting our traditional barn conversion gallery.

Hemp insulating/renovating plaster consists of a lime based binder mixed with chopped hemp. Hemp plasters have great acoustic and thermal insulative properties, and are around twice as breathable as lime. They can be built up to substantial thicknesses (around 2-3 inches is needed to acheive significant insulative qualities). Hemp plaster is ideal for rennovating old and draughty buildings as well as new build projects. Hemp plasters can be finished with breathable paints or skimmed with lime, depending on individual requirements.

Hemp insulating/renovating plaster consists of a lime based binder mixed with chopped hemp. Hemp plasters have great acoustic and thermal insulative properties, and are around twice as breathable as lime. They can be built up to substantial thicknesses (around 2-3 inches is needed to acheive significant insulative qualities). Hemp plaster is ideal for rennovating old and draughty buildings as well as new build projects. Hemp plasters can be finished with breathable paints or skimmed with lime, depending on individual requirements.

Hemp plasters are now available from a number of suppliers, including Ty-Mawr traditional and ecological building material suppliers. Tradical Hemcrete products are also available to infill stud walls, as screeds or as in situ cast roofing insulation. These and other natural building products are supplied in Devon by Back To Earth Natural Building Solutions. In Cumbria, Eden Lime Mortar manufacture and supply their own brand hemplime. For general information and how to buy a useful book all about hemp, look at Hemp Building advice from Steve Allin.

To find out more about insulating traditionally constrcuted buildings, see our breathable insulation page.

Any coating applied to a lime plastered or rendered wall needs to follow the same principles of breathability as the underlying layers. This means that the vast majority of modern paints (based on plastics) are not suitable for application over lime (this includes many that claim eco-friendly credentials). They will trap moisture and when subject to damp areas will bubble and flake from the surface.

Limewash and natural paints are the first line of defence in protecting lime plasters and renders from the elements and from general wear and tear. Becasue these are microporous/breathable, they will let damp pass through and dry naturally without harm to the wall or to the paintwork. Either through retaining the natural simplicity of lime white, or adding pigments of varying colours, they also add important aesthetic elements to every living space.

Limewash is made from lime putty mixed with water. It can be used white, or coloured with pigments (see our paint page for suppliers). On new plaster surfaces, we recommend the application of at least four layers of limewash to produce a homogenous surface. The finishes seen on many older buildings result from decades of annual limewashing: so the more coats, the better protected are the underlying walls.

There are many brands of breathable/microporous paint on the market, either ready mixed or provided as a base colour with added pigments to create personalised/specific colours. Read our breathable paint advice page or see our suppliers page for more information from individual manufacturers.

As external walls can be subject to significant water damage, the options for external breathable paints are relatively limited, see our external paint advice page for details.

Historically,‘spring cleaning ’ involved the application of limewash (whitewash), within and outside houses, barns and animal stabling. In many parts of the world, the annual whitewash remains part of the seasonal round, not only because of its cosmetic affects but also because lime is anti-fungal, anti-bacterial and antiseptic. As lime is also breathable, it also balances atmospheric moisture content, creating a healthy living environment. Cement based materials contain many toxic and potentially harmful chemicals linked with cancers and respiratory problems.

Historically,‘spring cleaning ’ involved the application of limewash (whitewash), within and outside houses, barns and animal stabling. In many parts of the world, the annual whitewash remains part of the seasonal round, not only because of its cosmetic affects but also because lime is anti-fungal, anti-bacterial and antiseptic. As lime is also breathable, it also balances atmospheric moisture content, creating a healthy living environment. Cement based materials contain many toxic and potentially harmful chemicals linked with cancers and respiratory problems.

As lime is produced at a relatively small scale, it has a lower carbon footprint and lower embodied energy rating (including transport) than cement products. The production of Portland cement is the third highest ranking producer of CO² in the world. Lime production gives off 20% less CO² than cement and lime actually absorbs nearly its own weight in CO² during the curing process (source: greenspec.co.uk).

Lime is very good at its job (and has been for centuries across the world) but it requires a bit of knowledge and understanding. Although some conventional builders⁄plasterers (and even architects) might tell you so, there’s absolutely NO NEED to mix it with cement, and there’s absolutely NO NEED for ‘base layers’ of mesh, or any ‘special coatings’ such as PVA. Such practices make a mockery not only of using a traditional material but also of lime’s inherent breathability and environmentally friendly credentials.

Lime is an important element in all traditionally constructed buildings. Where buildings have damp problems lime is often percieved to be 'the answer', especially where it is used to replace defective cement based renders and pointing. While this can be often the case, walls (especially those where chimneys and chimney flues are incorporated, or those prone to high levels of wind driven rain) may have other problems too! Lime is part of a holistic breathable system of tradititional building construction. Before you specify lime renders and mortars to solve problems, try and make sure that the walls under consideration are not subject to issues other than what the application of lime can achieve!

Please feel free get in touch if you need advice (or a price) and⁄or check out our further reading and links list which includes references to a number of helpful books and online resources. Also, Mike Wye and Associates produce very useful free guides and online literature regarding dampness and other problems in old buildings, breathability of lime and natural paints etc. Mike Wye Associates also run regular plastering courses in Devon.

Because lime is a traditional material, its application outside is dependent on seasonal conditions. Whilst inside plastering and painting can take place all year round, rendering and pointing are best done between frosts (April-September⁄October) and in the dry…

Jack in the Green Builders are based in north Devon, near Tiverton.

| home | cob | lime repointing | lath and lime repairs | carpentry | breathable paints | breathable insulation | links and suppliers |

|---|